Products

Our Products

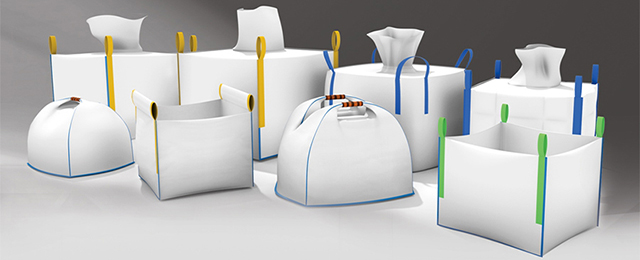

Looking for a reliable and cost-effective solution for your bulk material handling needs? Our FIBCs are the perfect choice. We offer a wide range of customizable options to ensure our products meet your exact specifications. Whether you need FIBCs for food-grade products, hazardous materials, or general industrial use, we have the right solution for you.

FIBC Types: A Comprehensive Guide

FIBC bags, also known as bulk bags or jumbo bags, are classified into four categories based on their static protection needs:

Type A

Plain bags with no static protection. Suitable for general-purpose applications where static discharge is not a major concern.

Type B

Bags designed with low breakdown voltage to prevent propagating brush discharges. Recommended for applications involving potentially combustible materials.

Type C

Groundable bags with interconnecting panels for effective static charge dissipation. Ideal for explosive environments.

Type D

Non-groundable bags that dissipate static charges through the atmosphere. Suitable for applications where grounding is impractical.

Design Types

Looking for a reliable and cost-effective solution for your bulk material handling needs? Our FIBCs are the perfect choice. We offer a wide range of customizable options to ensure our products meet your exact specifications. Whether you need FIBCs for food-grade products, hazardous materials, or general industrial use, we have the right solution for you.

Bag Designs

FIBCs can be categorized based on their bag design, which affects their handling, loading, and unloading capabilities. Here are some common types of FIBCs based on their bag design:

Circular Bag: Circular FIBCs are made from a continuous tube of fabric, creating a seamless design with no side seams. This can reduce the risk of seams splitting and increase the strength of the bag. It also provides a uniform shape, making it easier to handle and stack.

U-Panel Bag: A U-panel FIBC features a single, continuous panel that forms the bag’s base and sides in a U-shape, providing added strength and durability. This design often includes a reinforced bottom.

4-Panel Bag: This is a standard design where the bag has four panels (sides), providing a balanced shape. It’s commonly used for a variety of materials and is easy to handle and store.

6-Panel Bag: This design features six panels, offering a more stable and rigid structure compared to the 4-panel design. It’s often used for materials that require additional strength and stability.

Baffle Bag: Baffle bags have internal baffles or support panels that help maintain the shape of the bag, preventing bulging and providing a more stable structure. This design is useful for maximizing storage space and improving handling efficiency.

Cross-Corner Bag: Cross-corner bags have lifting loops attached at the corners of the bag’s base, which allows for balanced lifting and improved stability during handling. This design is useful for applications requiring precise lifting and transportation.

Top Designs

Flexible Intermediate Bulk Containers (FIBCs), also known as bulk bags, come in various designs tailored to specific needs. Here are some common types based on their top design:

Open Top: These FIBCs have an open top, which allows for easy filling. They are often used when the filling process does not require a closure or when a cover is not necessary.

Spout Top: This design features a narrow, tube-like opening at the top that can be closed with a tie or flap. It allows for precise filling and can be equipped with a spout that facilitates easier pouring or discharge of contents.

Duffle Top: A duffle top has a large, fold-over flap or cover that can be secured with ties or straps. It provides a secure closure during transport and can be opened wide for easy filling.

Skirt Top: A skirt top features a wide, overhanging flap or skirt that can be folded down and secured. It provides extra protection against contamination and spillage.

Cone Top: This design has a conical or tapered shape at the top that helps in better control of the filling process, especially for powders or granular materials.

Bottom Designs

The bottom design of a Flexible Intermediate Bulk Container (FIBC) can significantly impact its stability, handling, and discharge efficiency. Here are some common types of FIBC bottom designs:

Block Bottom: A block bottom design has a reinforced, flat base that provides a sturdy foundation, enhancing stability and making the bag easier to stack. It is particularly useful for heavy materials and for applications where stability is crucial.

Discharge Spout (or Spout Bottom): This design includes a spout at the bottom of the bag for controlled and efficient discharge of the contents. The spout can be equipped with a closure mechanism, like a tie or flap, to prevent spillage and facilitate precise unloading.

Gusseted Bottom: A gusseted bottom features pleated sides that expand to accommodate more material and provide additional volume. This design allows the bag to expand as it is filled and helps in maintaining a more compact shape when handling.

Valve Bottom: This type features a valve mechanism at the bottom for controlled discharge. The valve can be opened or closed as needed to manage the flow of material, making it suitable for applications requiring precise control.

FAQ

What is an FIBC and how does BTA BULKBAGS specialize in them?

An FIBC (Flexible Intermediate Bulk Container) is a large, flexible bag used for storing and transporting bulk materials like powders and granules. At BTA BULKBAGS, we specialize in producing high-quality FIBCs that are designed to meet various industry needs, ensuring durability and efficiency for all your bulk handling requirements.

What types of FIBCs does BTA BULKBAGS offer?

BTA BULKBAGS offers a wide range of FIBCs, including:

- Open Top Bags: Easy to fill, ideal for straightforward applications.

- Spout Top Bags: For precise filling and controlled discharge.

- Duffle Top Bags: Featuring secure flaps for added protection.

- Baffle Bags: Designed for stability and shape retention.

- Block Bottom Bags: For a sturdy, stable base, ideal for stacking. Explore our full range to find the perfect FIBC for your needs.

How can I select the right FIBC from BTA BULKBAGS for my specific application?

To choose the right FIBC, consider factors like the type of material you are handling, required weight capacity, and filling/discharge methods. At BTA BULKBAGS, our experts can guide you through selecting the most suitable FIBC based on your specific requirements and application needs.

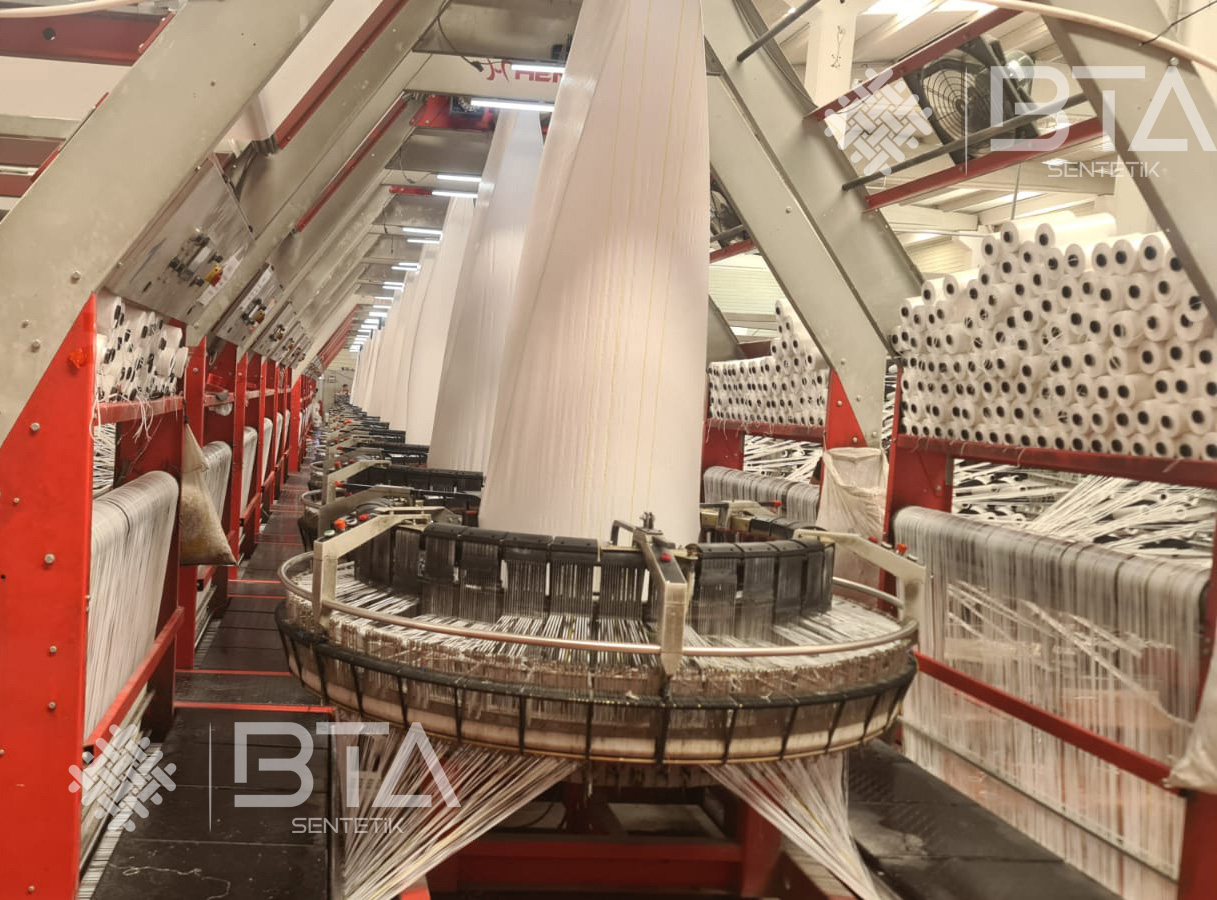

What materials are used in BTA BULKBAGS FIBCs, and what are their benefits?

BTA BULKBAGS uses high-quality polypropylene for most of our FIBCs, offering excellent strength and durability. We also provide options like coated fabrics for moisture resistance and conductive fabrics for handling sensitive materials. Each material is chosen to enhance performance and safety based on your requirements.

What are the weight limits of BTA BULKBAGS FIBCs?

BTA BULKBAGS FIBCs come in various weight capacities, typically ranging from 500 kg to 2000 kg (1100 lbs to 4400 lbs). Our bags are designed to handle different weights and volumes, ensuring that you can find an FIBC that meets your specific load requirements.

How should I properly store BTA BULKBAGS FIBCs before use?

Store BTA BULKBAGS FIBCs in a dry, cool place, away from direct sunlight and chemicals. Ensure they are not stacked in a way that could cause damage. Proper storage helps maintain the quality and performance of your FIBCs.

Can BTA BULKBAGS FIBCs be reused or recycled?

Many BTA BULKBAGS FIBCs are designed for single-use, but some can be safely reused if they are clean and in good condition. Our FIBCs are made from recyclable polypropylene, which can be processed and repurposed. Check with us for specific recycling guidelines and options.

What safety measures should I follow when using BTA BULKBAGS FIBCs?

To ensure safety when using BTA BULKBAGS FIBCs, follow these guidelines:

- Use appropriate equipment for filling and discharging.

- Ensure the bag is properly supported and secured.

- Adhere to recommended weight limits and handling procedures.

- Follow proper storage and maintenance practices to prevent accidents and ensure optimal performance.

Discover the Perfect FIBC Solution for Your Business – Get a Free Consultation with BTA BULKBAGS Today!

Act Now to Unlock Customized Bulk Solutions and Exclusive Benefits – Connect with BTA BULKBAGS for Expert Guidance and Tailored Recommendations!